de Velde

June

June consists of a service and product.

It continually searches for the best market price, automatically changes your energy contract and consists of a smart meter reader that can continuously read your meter and send it to the cloud where all data is displayed in an interactive dashboard. The function of June is to dissuade people, to help them saving on their energy bill, to understand their consumption and to reduce the threshold to green energy.

June provides energy services and products for users to save money on their energy bill without any hassle. It helps customers save on their energy bill by lowering the invoice by switching customers automatically between energy suppliers based on their personal preferences and usage and by providing energy insights and services to lower customers consumption or help them to decide on domestic local production & storage.

June constantly looks for the best energy market price and switches you automatically between suppliers when you can save money. She measures your energy consumption and compares your personal situation and consumption with all available prices and promotions. When you can save money June switches you automatically and centralizes all energy invoices in the June platform so you don’t have to deal with any hassle.

June customers manage all of their home energy in the online platform. They can see their usage, savings and invoices. Of course customers can indicate their preferences regarding green energy and access all insights and analyses.

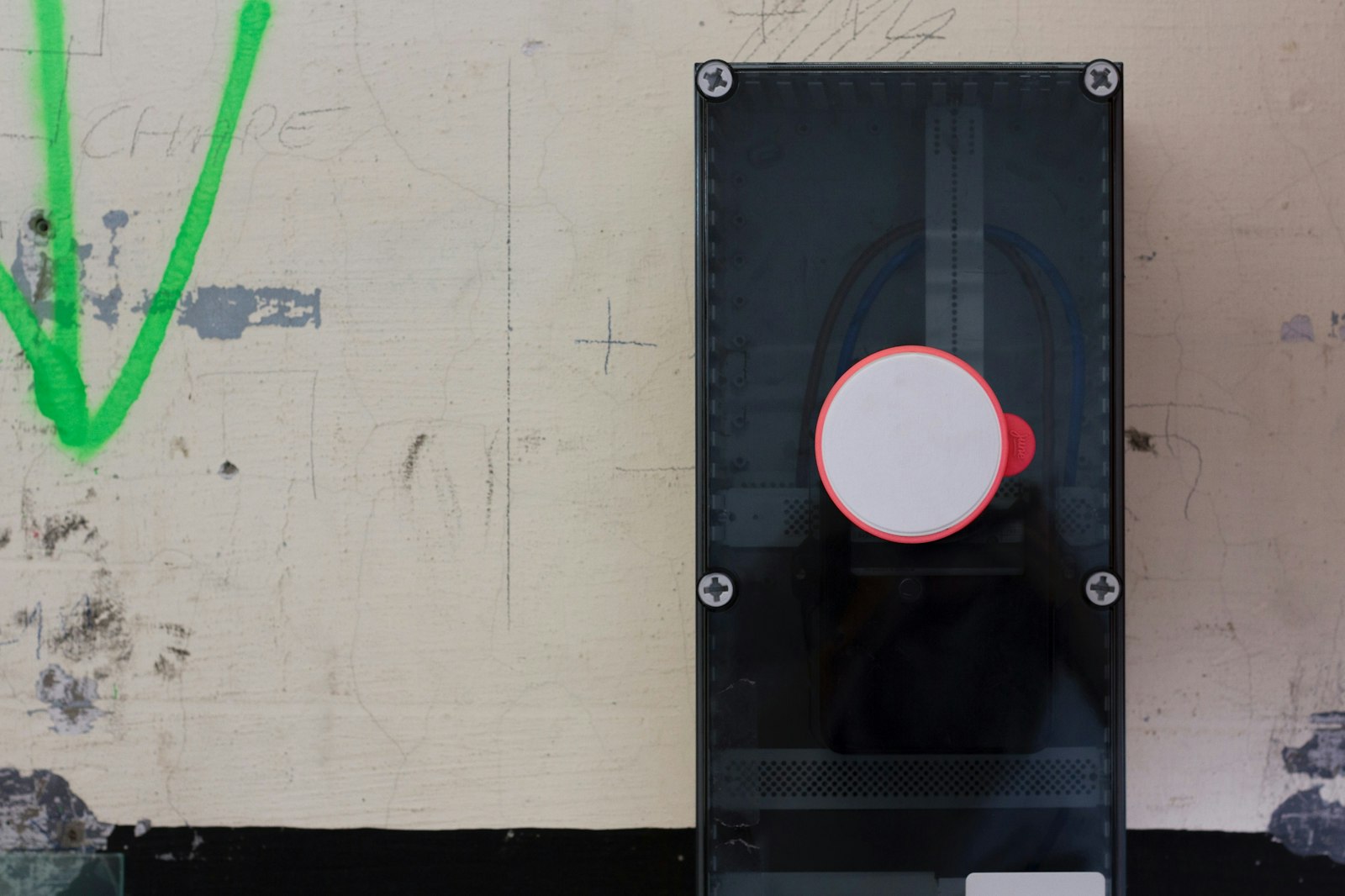

To overcome the connectivity problem, Bagaar chose to design two devices that can communicate with each other, one is located on the utility meter and another one close to an internet access, WiFi or LAN. The communication between both is done over a low frequency protocol that works well in places with limited access, for example in basements and in concrete buildings with poor wireless connection.

Playing with color and changing mould-inserts during production helped to differentiate the devices. Secondly, all rigid parts are snap fitted together and are fixated with a flexible ring around them, reducing the assembly time of the product. This made it possible to work with local suppliers for the moulds, for the production of the casing, as well as for the assembly and the packaging of the product.