de Velde

Dynamx

The innovative dynamx control valves regulate energy flow to bring the right amount of energy to the right place at the precise time.

Water supply (warm and cold) is continually adjusted to maintain the preferred comfort level in each room. Thanks to variable flow rate control, the temperatures can be determined precisely for each room independently and regardless of occupancy.

The innovative dynamx control valves regulate energy flow to bring the right amount of energy to the right place at the precise time. Water supply (warm and cold) is continually adjusted to maintain the preferred comfort level in each room. Thanks to variable flow rate control, the temperatures can be determined precisely for each room independently and regardless of occupancy.

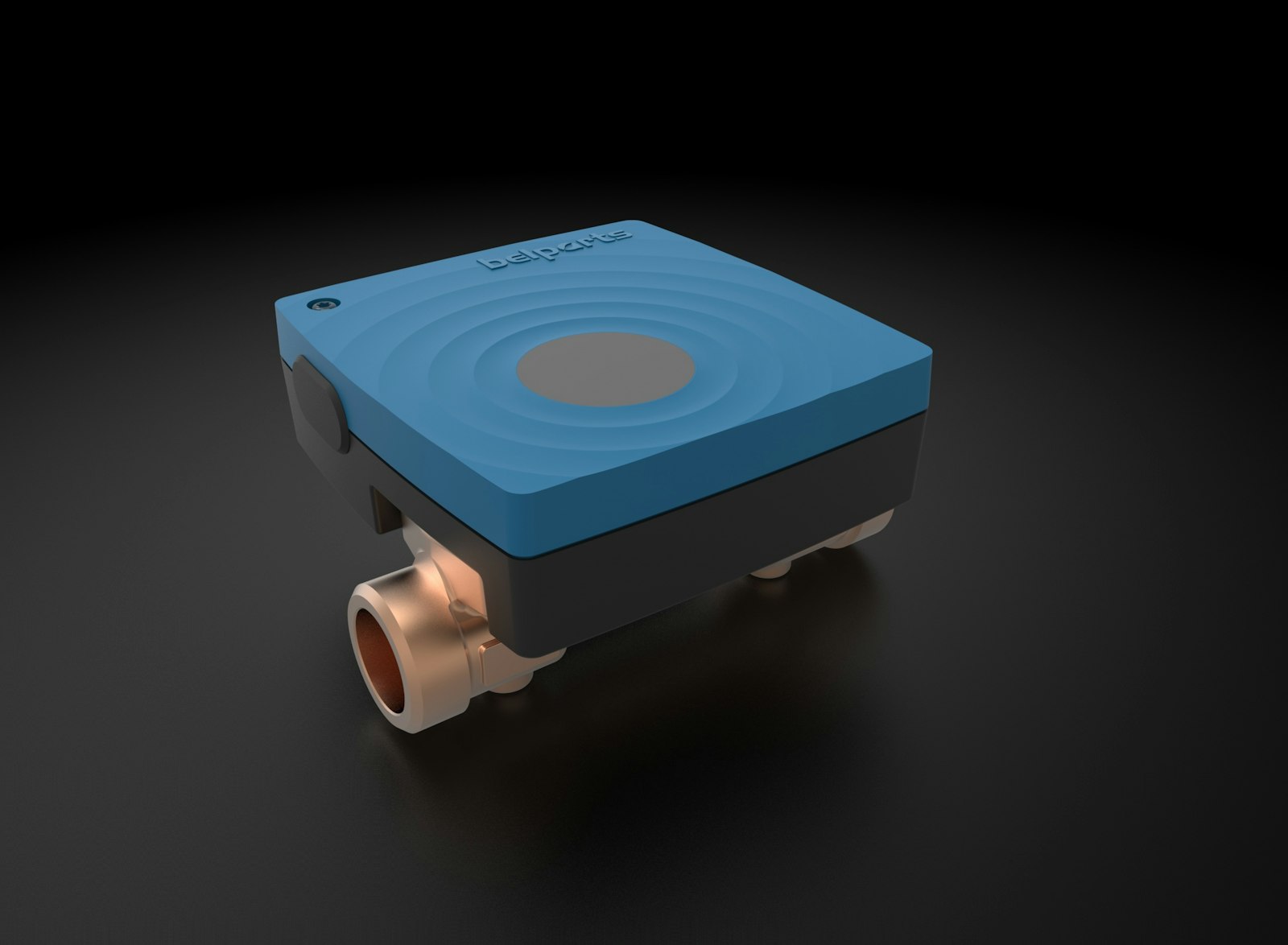

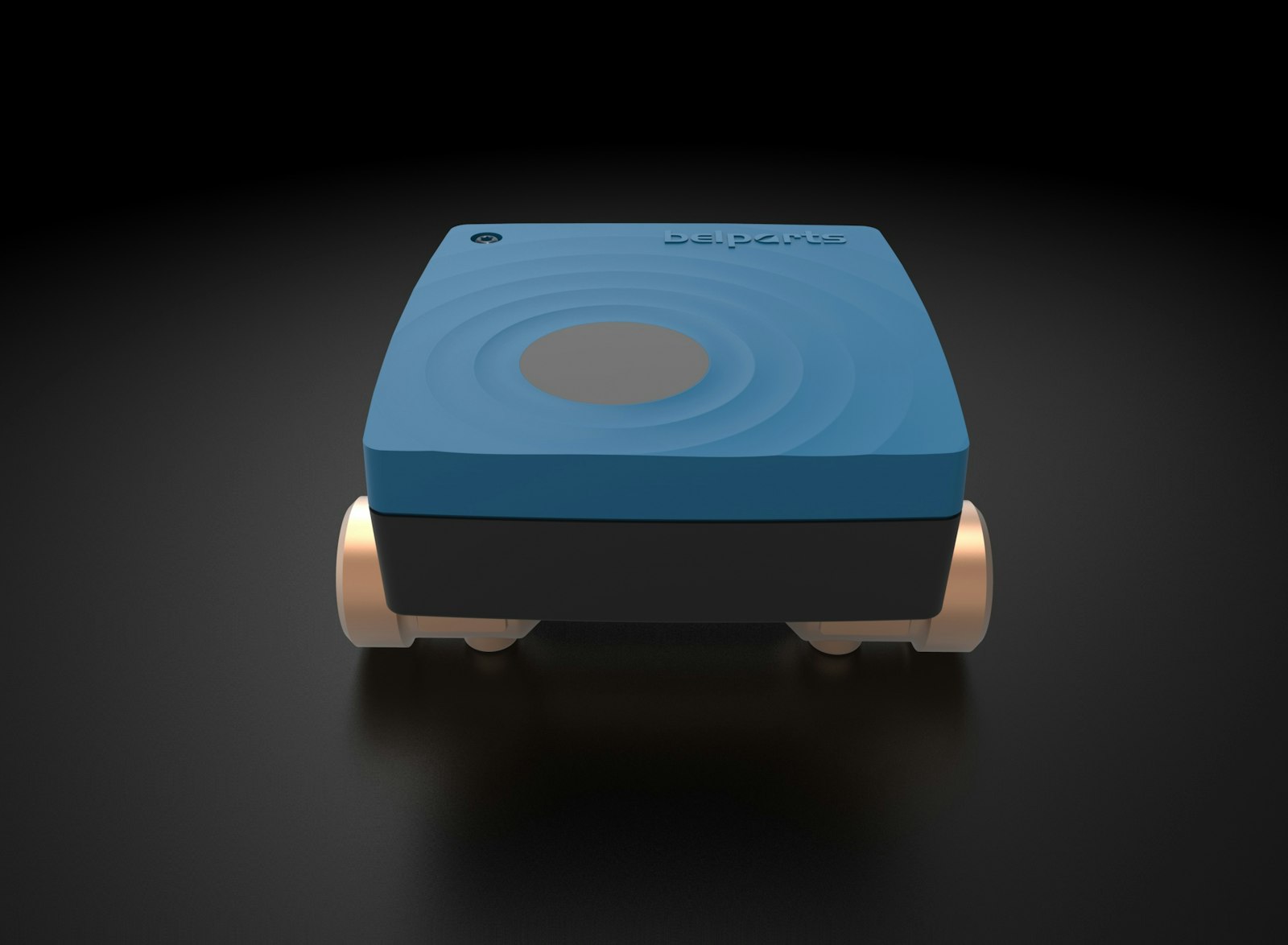

The Dynamic Flow Networking (DFN) concept gathers precise information about the energy levels on each floor of the building. Each room is fitted with a dynamixTM control valve which is coupled to a thermostat and control unit. These units communicate to the Building Management System (BMS) for monitoring.

This information sent to the BMS is used to control the primary pumps so that the appropriate amount of hot and cold water is fed to each floor. Energy is conserved in this way, by using only the necessary amount of water. Consumption and energy performance can also be tracked by room or floor, and alarms can be automatically triggered in the event of a problem. The result? Optimal comfort at lower energy cost.

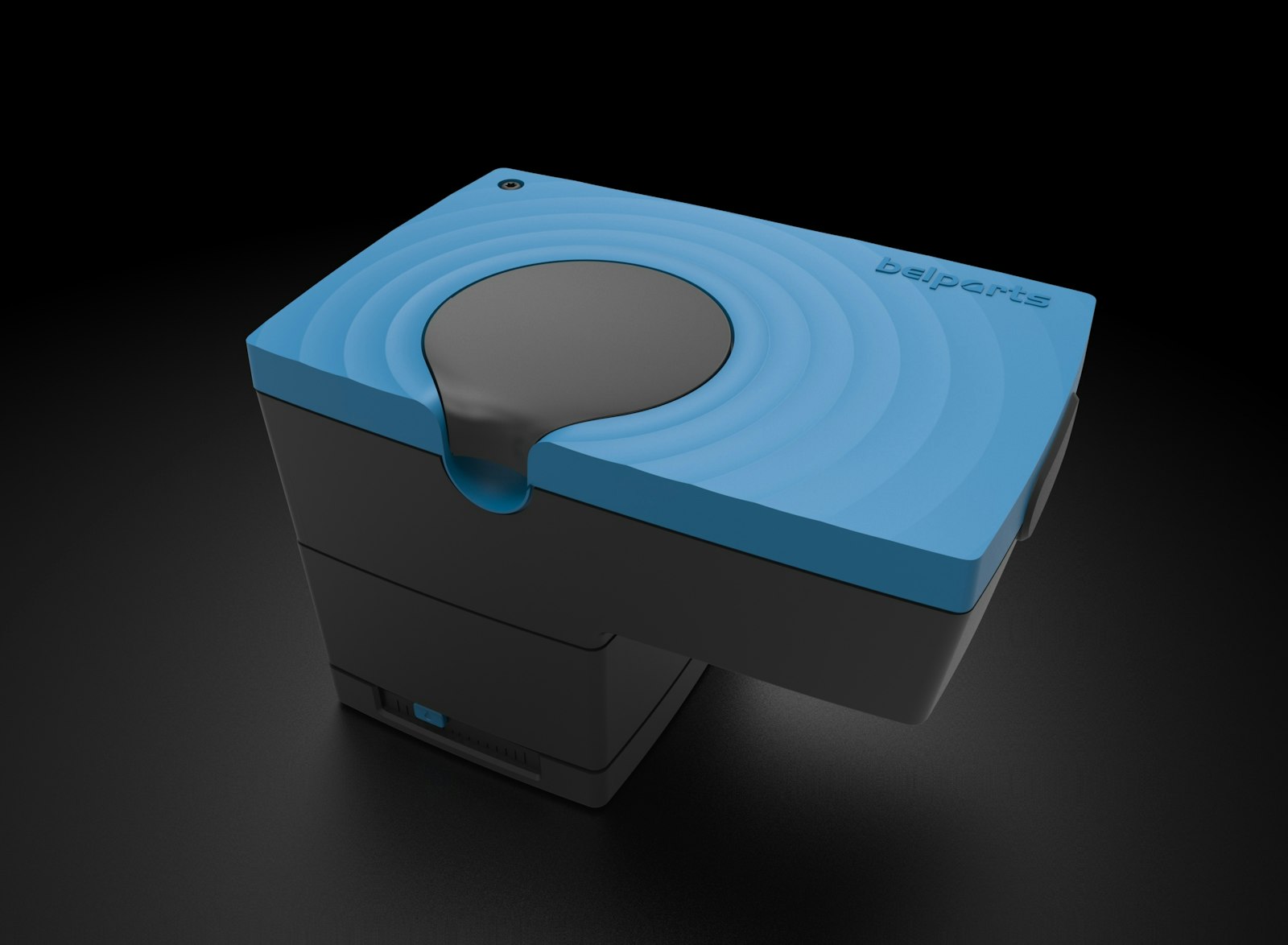

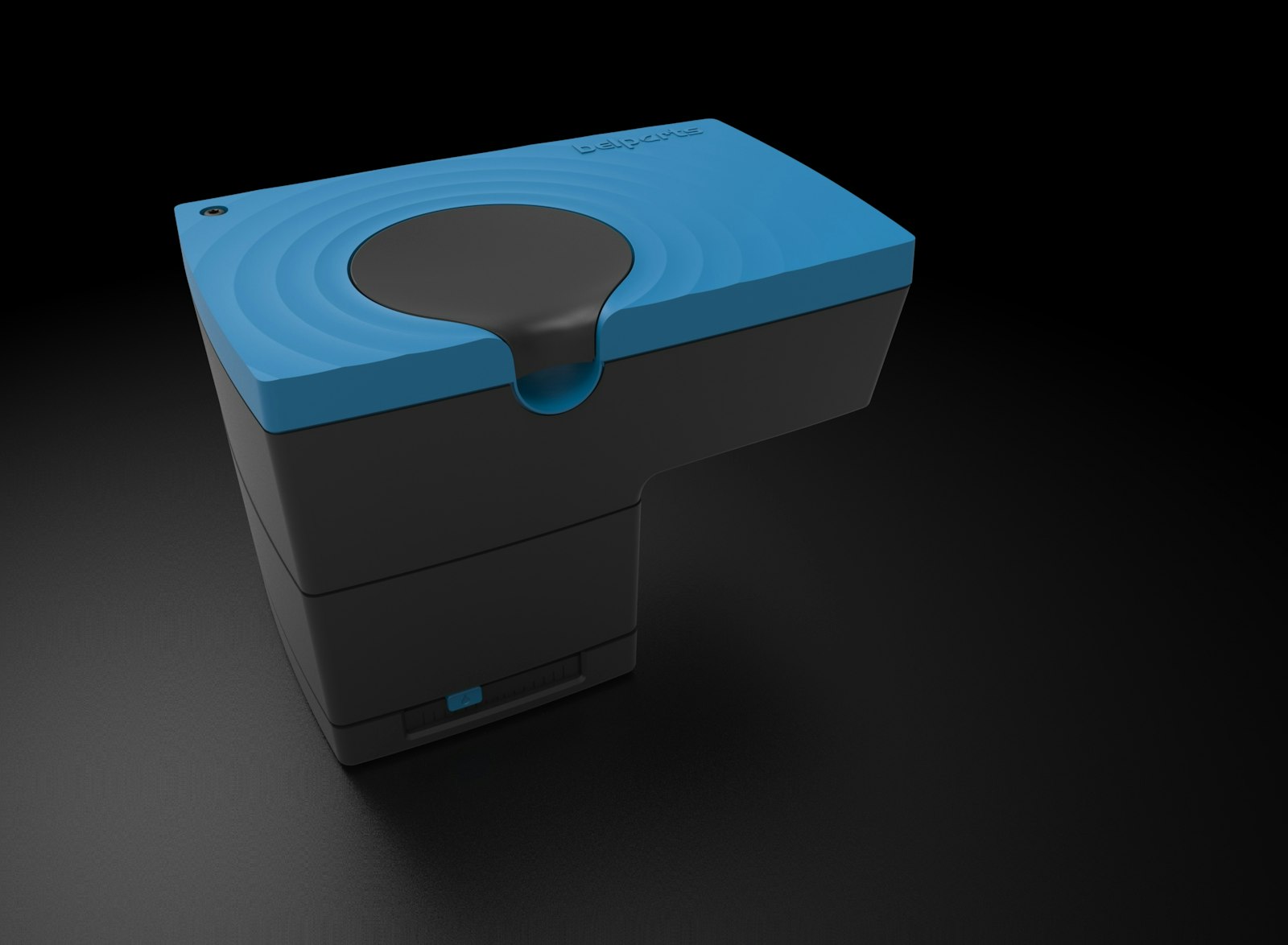

The product line includes a motor and sensor unit, to be used independently or in combination with one another. Both are modular so they may be configured in function of application: with or without built-in displays, the input of additional external sensors, or wireless communication to read the field data.

Belparts created an innovative terminal control valve according to the principles of Dynamic Flow Networking: dynamx. Dynamx replaces the classic terminal control valve, noting the following essential differences:

- Balancing function: the additional balancing valve becomes obsolete, as the balancing is carried out by the dynamx valve itself.

- Pressure independent: dynamx uses a patented** mechanism to detect pressure variations. The pressure variations are compensated through electronic flow measurement.

- Energy monitoring: dynamx measures the momentary flow, water temperature differential ΔT and the power consumed.

- Life-time commissioning: Every dynamx device can be commissioned and recommissioned remotely, answering the varying needs of the infrastructure.