de Velde

Materialise

Founded 25 years ago by Wilfried Vancraen, Materialise has since grown into

a leading international player in additive manufacturing (also known as 3D printing), the software needed to drive 3D printers and research into applications in the biomedical sector.

“For quite some time, 3D printers were used exclusively to make prototypes for such sectors as the automotive industry, but Materialise was one of the first to use this technology within a broader field of application,” proclaimed the jury. “Materialise has given the world and its designers a tool to transform 3D-printed designs into concrete objects and to use these, meaning 3D printing can now be considered a fully-fledged production technique. Not only does this technology enable professionals to supply highly specific parts and components, it also enables the public at large to experiment with this independently. The ‘MGX by Materialise’ collection of lamps is hands-on proof of the potential of this technology and the 2009 i.materialise website was one of the first tools allowing consumers to independently design and make products. Materialise is not a manufacturer in the traditional sense, but a platform that deploys its own expertise in the broadest and most contemporary way possible. In short, Materialise not only combines industrial manufacturing with innovation, but also with emotion and poetry. And it does all this at an international, cutting-edge level. Flanders and Belgium can justly take pride in this accomplishment.”

From a pioneer to a backbone in the industry

In July 1990, Wilfried Vancraen founded Materialise NV where he remains the CEO to this day. Over the past 20 years, he has succeeded in turning Materialise into a highly respected organization with a reputation for innovation and over 1 300 employees in offices worldwide.

Established as the first rapid prototyping service bureau in the Benelux region, Materialise is now Europe’s largest single-site factory for 3D printing. Immediately following its conception, the company concentrated on researching and developing solutions for the transfer of data to rapid prototyping machines. This resulted in the commercialization of Magics and Mimics, innovative software solutions which helped cement Materialise’s leading position in the market today for design automation, product customization and much more. Since its release, 3D printing professionals have been able to turn to Magics in order to get the most out of their projects. Likewise, the Mimics Innovation Suite has become the solution of choice for medical-image-based biomechanical engineering. With a range of software solutions to bridge the gap between meaningful applications and 3D printing systems, Materialise Magics is the backbone of the 3D printing industry.

Through the work being done with Mimics, Mr. Vancraen identified the potential to use additive manufacturing to further patient-specific healthcare. Over the course of the past 25 years, this has resulted in a large variety of solutions for surgeons, hospitals, implant and medical device companies, as well as biomedical researchers and institutes. Materialise medical software solutions allow surgeons or researchers to convert medical image data into an accurate, virtual 3D model, which they can use to augment their analyses, designs and modeling.

SurgiCase CMF and SurgiCase Orthopaedics, along with laser sintered surgical guides and anatomical models brought patient-specific treatment to new levels. Through the solutions offered by Materialise, surgeons and clinicians are able to collaborate with experts in the company to create and adapt surgical plans, find creative solutions to difficult cases, and put the plans into action in the operating room. These capabilities led to an exciting project in 2005 when Mr. Vancraen launched RP4Baghdad, a philanthropic mission which brought the advantages of these solutions to civilian victims of the Iraq war. Eventually, the acquisition of OBL in 2007 broadened expanded Materialise’s repertoire to include titanium implants for cranio-maxillofacial surgery, neurosurgery and plastic surgery.

Through Materialise, Mr. Vancraen has also brought the advantages of 3D printing to individual consumers through i.materialise, an online service offering individuals the opportunity to bring their ideas to life through 3D printing. Launched in late 2009, i.materialise has grown considerably over the past year in terms of both the services it provides and the coverage it gets in the press. Mr. Vancraen sees i.materialise as an important step in the evolution of Materialise and much attention will be given to the service in the coming years. Industry and medicine have long benefited from 3D printing, and it is time for individual consumers to discover and try this technology themselves. (Editor's note: this text is written in autumn 2015)

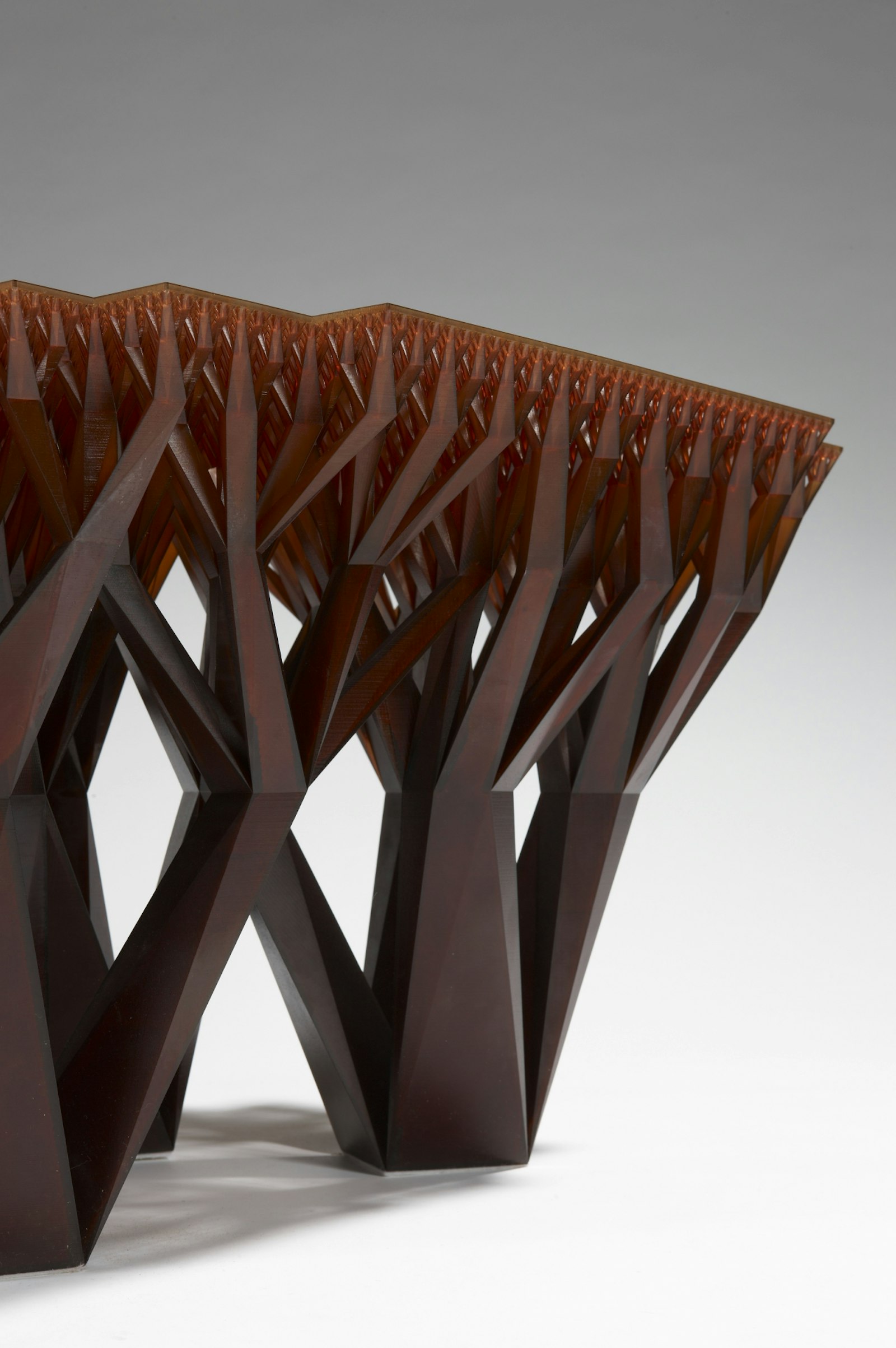

In addition, Materialise pioneered the use of 3D printing for consumer goods through .MGX by Materialise, a celebrated line of high-end design products created in collaboration with some of the greatest names in design today. .MGX creations have featured in top design publications, have made their way into the permanent collections of world-class museums including the MoMA in New York and the Centre Pompidou in Paris, and have an ever expanding collection of prestigious awards to their credit.

Soon after growing into a company of over 1 000 employees in June 2014, Materialise announced its initial public offering. Within the year, the company made strides of growth in all three business areas — engineering, medical and consumer applications — with the acquisition of leading Polish prototyping center e-Prototypy, the acquisition of OrthoView, market-leading 2D digital pre-operative planning provider for orthopaedic surgeons, and the launch of the initiative ‘Ideas Worth Making’ to encourage educational applications of 3D printing.

On the occasion of its 25th anniversary in 2015, Materialise provided 3D-printed exhibits for an installation titled Making a Difference/A Difference in Making, hosted at Bozar in Brussels. 15 000 visitors came to experience how 3D printing is changing the world around us as well as changing the manner in which we create. In October 2015, Materialise opened a metal printing factory in Bremen, marking the company’s next step in becoming the most complete factory for 3D printing. The same year also marked a step forward for Materialise’s collaboration with Bruges-based eyewear specialist Hoet design studio, for the 3D-printed Cabrio Collection. When Hoet and Materialise worked with SEIKO Optical Europe for the SEIKO Xchanger collection of sports eyewear, the partnership won the prestigious Silmo d’Or award for excellence in optical innovation, in acknowledgement of the added value which 3D printing brings to the eyewear industry.

In recognition of Mr. Vancraen’s and Materialise’s many contributions to the 3D printing industry as well as others, Mr. Vancraen has received a number of awards over the years. In May 2011, Mr. Vancraen received the prestigious RTAM/SME Industry Achievement Award. The award was developed to recognize an individual, team or company for outstanding accomplishments that have had significant impact within the additive manufacturing industry or in any industry through the application of 3D printing technologies. This award confirmed Mr. Vancraen’s role as a game changer in the AM industry. Furthermore, with this extra encouragement, he is more committed than ever to spreading the benefits of 3D printing technology, creating a truly better and healthier world.

He was again recognized as a leader in the additive manufacturing industry in June 2012 when TCT Magazine placed him in the top position for their list of the Top 20 People in AM/3D Printing. Likewise, the Financial Times listed him as one of the 5 leading players in the industry on 15 June 2012. He was also the recipient of a 2013 Visionaries! Award from the Museum of Art and Design in New York, and of a sign of honor from the Flemish government in 2015 in recognition of his contribution to the image of Flanders. And now the Henry van de Velde Company Award 2015!