de Velde

Unfold

The problem was traced to Relay #70 on Panel F, where the operators discovered an intruder in the system. The event was duly recorded in the log on 9 September 1947: ‘First actual case of bug being found,’ written below a moth taped to the paper.

The anecdote reveals something that has largely been forgotten as digital technology became pervasive, microscopic, and black-boxed beneath impenetrable glass and aluminium. The computer of 1947, assembled at an architectural scale — 18 metres in length, with a 2.5-metre high front panel — retained not only an overwhelming sense of material physicality but also a sensitivity to the capricious behaviours of its environment and the organic bodies contained therein. Though the machine operated by different logics, it was entirely ensconced within a natural system of chance encounters, sparks, fumbles, and the odd winged creature.

Design itself has struggled with this precarious membrane between the analogue and digital realms, although its initial confrontation with that frontier is difficult to locate precisely. The onset of industrial production, for example, could be considered the first step towards a reproducible script, oblivious to the individual authorship of the various figures involved in its manufacture, but it might equally be seen as a mere progression of the repetitive motor skills of the disciplined craftsman. The 1960s and ’70s breakthroughs in 3D modelling, from the wire-frame Boeing man to real-time drawing in a graphic interface, tread a similarly equivocal line between mathematical representation and design. Still, as in the moth, the shift into the digital realm produced several conclusive artefacts that can be used to mark its borders.

One case is the Utah teapot, a virtual geometry created in 1975 by Martin Newell to explore the basic problems of 3D modelling and rendering. Based on a Melitta teapot, the original Utah was shorter, due to the use of non-square pixels, and lacked a bottom, since it would not be viewed from below. In 2009, the Belgian design studio Unfold recreated this design as a working teapot, cast in white porcelain from a 3D-printed mould. The Utanalog is an iconic anachronism, transposing the faceted surfaces used on the computer to ease the burden of graphic resolution into the real world, where the smooth curves of the archetypal teapot are both an outcome of the rotational geometry of the pottery wheel and a functional asset for liquid-bearing vessels.

As the founders of Unfold, Claire Warnier and Dries Verbruggen have continuously orchestrated these kinds of conversations between the fields of physical making and digital form-giving. As ad-hoc interpreters who speak neither the mother-tongue of computer code nor that of traditional craft, they create unusual scenarios of confrontation between the two in which the untranslatable, the idiomatic and the unexpected are foregrounded against a field of normative design practice. At the same time, each of their projects also explores one of myriad tangents of the digital-analogue divide, building a line of inquiry into issues such as technical proficiency, intellectual property, and the uniqueness of the identical object.

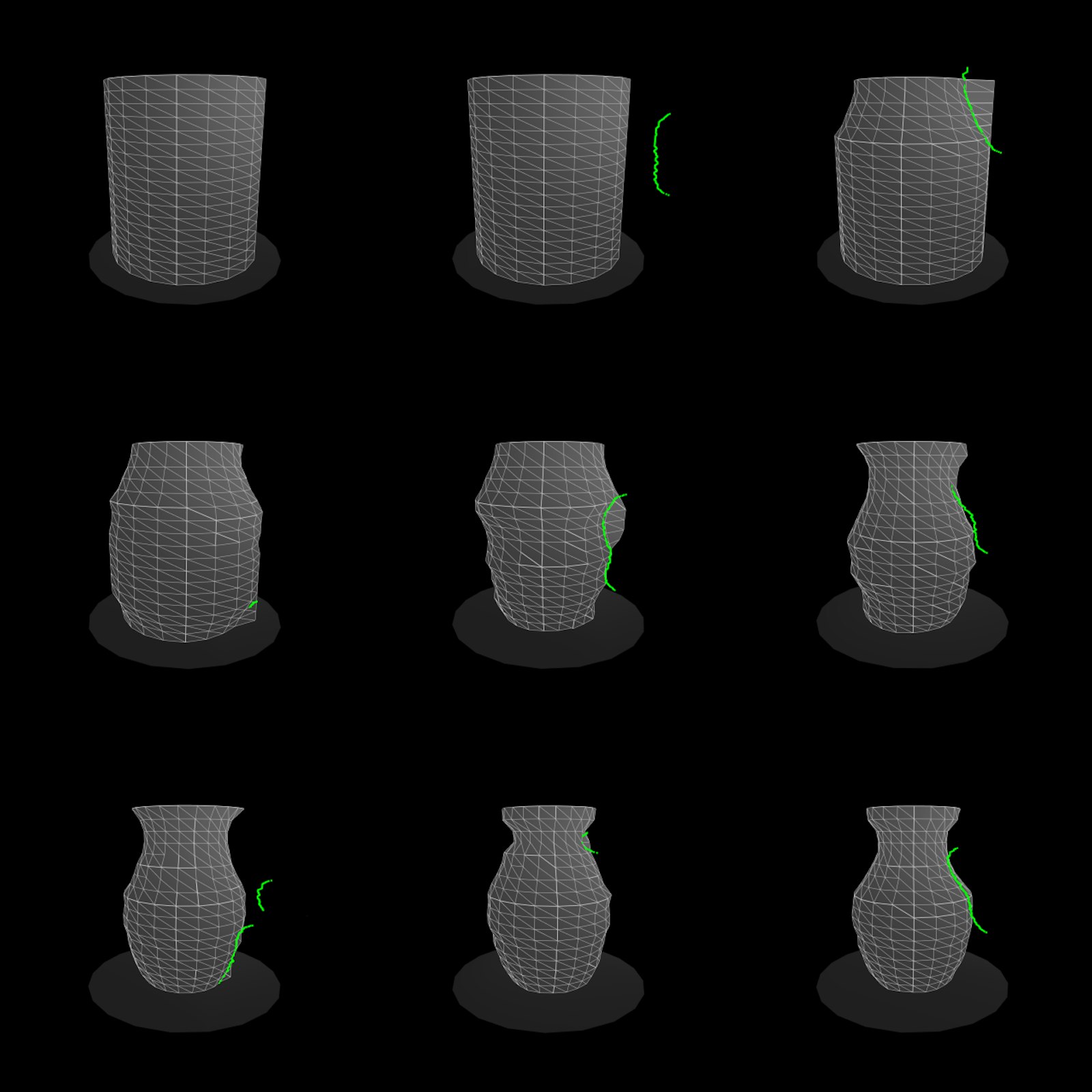

L’Artisan Electronique (2010), for instance, questions what obstacles lie between skilled production and the casual user, as well as the implications of the digitalisation of physical tools. As a virtual cylinder spins on a computer screen, the user cuts away and elaborates its shape by passing his or her hand through a laser. The user can then see the live evolution of a vase-like silhouette determined by their physical input. When satisfied, he or she adds the design to an archive of shapes, which can then be fabricated through a process of digitally-controlled clay deposition on a printer bed, not unlike the traditional process of building pots with long coils of rolled-out clay.

On first glance, the project might seem a reductive approach to wheel-throwing, bringing an illustrious craft that has evolved over millennia of human development to the level of a four-button Guitar Hero. Rather than a proposal for mainstream consumer production, however, L’Artisan Electronique is actually a set of layered premises that challenge preconceptions about both handcraft and digital design. For the first-time user, the tool does have a more gentle learning curve than the pottery wheel, where the desired form must combat the overriding factors of clay consistency, moisture, temperature, speed, and the strength and dexterity of the human hand as well as its extensions (knives, ribs, and wires). However, it is much more difficult to create the perfect symmetry that comes so readily in 3D modelling programmes, and the complex faceted surfaces produced on the virtual wheel are more the byproduct of human imperfection than the demonstration of digital sophistication. Furthermore, Unfold’s design dispenses with the electronic palette of discrete digital tools (Boolean operations, extrusion, scaling, and tweening, among many others) for an indeterminate spectrum of manual manipulations of a virtual solid. Finally, the project introduces a new dynamic of creation: deprived of the resistance of wet clay, even the master’s hand may find a new challenge in moulding thin air.

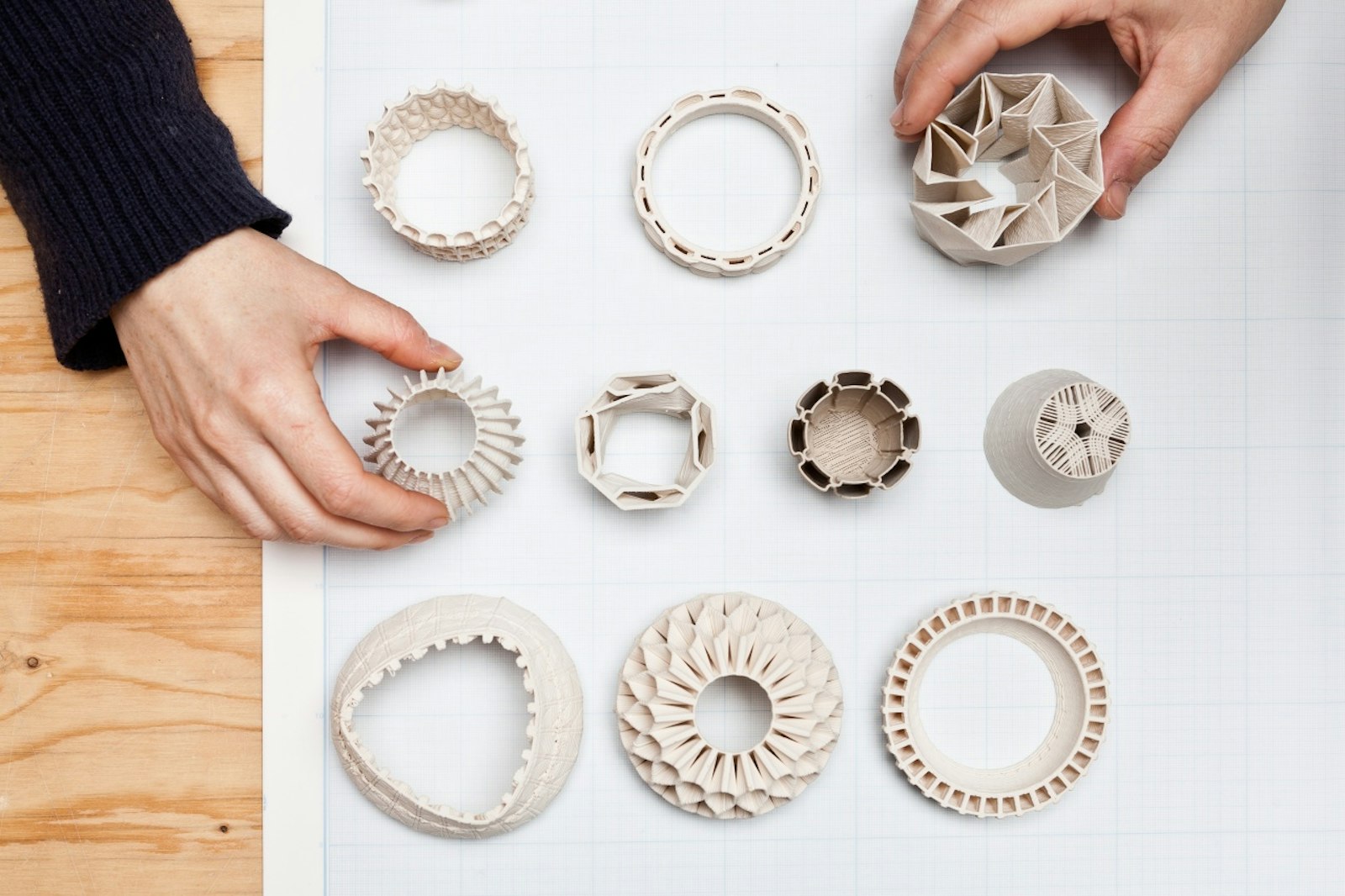

While L’Artisan Electronique experiments with infinite variations on form, the basic tenets of the Stratigraphic Manufactury platform are diametrically opposed. Here, Unfold utilises the endless transferability of digital code to overcome physical challenges in the production of identical forms in disparate locations. Where industrial ceramics manufacturers once had elaborate systems in place to reproduce and maintain their archetypal masters and moulds, Stratigraphic Manufactury disseminates virtual geometries across a global network of small producers, who realise the unaltered files on open-source RepRap 3D printers customised to deposit liquid clay. Beginning in 2012, Unfold has expanded the network from Belgium to Suffolk, Tel Aviv, Istanbul, New York, London, and Taipei, working with a range of traditional craftsmen, artists, and digital designers.

When seen together, the collection of cups, plates, and vessels produced all over the world reveals how much the output of an ‘identical’ form can vary when multiple parameters come into play. Some customisation can take place on the machine itself, by altering the thickness of the deposited line of clay (and thus the thickness of the wall), while other variations emerge from intentional changes to the specific kind of clay composition and colour (from Wedgwood jasperware to New York river sludge) or to the choice of glazing. Of course, unplanned circumstances also prove influential, from manageable shifts in environmental temperature and humidity to failures in the printing process. Like Natalie Jeremijenko’s One Trees (1998), in which one thousand cloned trees were cultivated and planted around the city of San Francisco to measure the interactions of identical genetic code with particular local contexts, Stratigraphic Manufactury maps not only the biological, chemical, and geological preconditions for manufacture but also their interactions with local cultural traditions and aesthetic preferences.

These projects, situated within a broader rumination on entirely contemporary and largely intractable issues of authorship, authenticity, translation, and reproduction, reveal the singularity of Unfold’s position in a design field in constant flux. Skilfully sidestepping the moral appeals that tend to latch onto themes of craft or technological progress (especially the replacement of one by the other), their work treats design as a unified panoply of techniques and tools for the transformation of matter, from liquid clay to fired ceramic, from binary code to tangible object, from empty air to something you can hold in your hands. And rather than simply accept those techniques and tools as given, they constantly investigate, question, and reinvent them. By complicating the accepted narrative of humans, tools, and machines, Unfold opens up cracks and traces loopholes in which diverse ideas and influences unexpectedly meet, synthesise, and produce a new space for design to evolve.